Types and Sizes of Sewing Needles

One of the most frequent errors we see is using the incorrect kind of sewing machine needle. It may result in needle breakage, difficulties working with the cloth selected, and poor stitch quality. When you run into one of these issues, first, just laugh it off with a funny sewing quote. Then, with our sewing needle guide below, you’ll never have to deal with these issues again!

In this article, we discuss the many needle kinds available as well as the fabrics and threads that they should be used with. Even if you’re an experienced stitcher who knows all there is to know about needles, it’s worth a brief read. You could be surprised to find a life-changing needle you didn’t even know existed! Once you get the correct needle and are ready to sew, why not try out one of our sewing patterns?

Types of Needles for Sewing

First, remember that sewing machine needles follow a standard so that they work across a variety of brands. At first, the sheer quantity of various kinds and sizes of machine needles might seem overwhelming. Getting a grip on the varieties, on the other hand, isn’t that tough. We’ve compiled a list of the most common needles, as well as the methods and materials for which they’re utilized.

Universal Needles

Universal needles, as the name implies, are the most generally used needle. They can be used with woven textiles, synthetics, and certain knit fabrics. However, other needle types are available for specific kinds of knit fabric. Lightweight materials are usually sewn using finer needles. Medium to heavyweight textiles requires larger sizes. A universal needle should be used with polyester, cotton, or silk threads.

Ballpoint Needles

Ballpoint needles have a more rounded tip than universal needles. Instead of cutting the cloth fibers, they push them apart. These needles are excellent in preventing running or laddering on rib knits, interlock, cotton knits, fleece, double knit, and other knit materials. Always remember that ballpoint needles should be threaded with polyester or polyester/cotton mix threads, while finer needles should be threaded with finer threads.

Sharps Needles

If you’re quilting with many layers of cotton and wadding, or if you’re working with densely woven fabrics like silk and microfiber, you’ll need a sharps needle. These needles are designed to function with many layers of fabric. They have a stronger shaft that prevents bent or broken needles and a sharp point that allows them to pierce the cloth and make flawless buttonholes. A short round threading eye also adds strength to the stitching process.

Quilting Needles

Quilting needles, like sharps needles, are intended to stitch through many layers of fabric and wadding. However, they are significantly shorter in length than sharps needles, allowing quilters to stitch quickly and evenly. Beginners will usually choose a smaller needle, such as a size 7 or 8. However, more experienced quilters would prefer a bigger needle.

Embroidery Needles

Embroidery needles have a broader eye to enable machine embroidery threads like rayon, polyester, or cotton to flow freely and effortlessly during embroidering. When machine embroidering, missed stitches are common due to the cloth stretching up and down swiftly as a consequence of the fast-moving embroidery thread. Embroidery needles feature a pontoon scarf with an enormous hump. This decreases the amount of movement in the cloth, minimizing the probability of this occurring.

Stretch Needles

Stretch needles have a scarf that lets the hook pass close by and avoids skipped stitches. This makes them suitable for materials like Lycra, power net, two-way stretch knits, silk jersey, spandex, and highly elasticated synthetic textiles. Polyester threads wrapped in cotton should be utilized. Stretch fabrics are notorious for being more difficult to work with! So, selecting the appropriate needle is critical to a successful outcome.

Jeans Needles

There are no rewards for guessing which cloth these needles were made for! Yes, denim is the obvious option, but these needles are also ideal for tightly woven fabrics like heavy twill, canvas, and heavy linens, which are often used for workwear. Unlike stretch and ballpoint needles, which are meant to avoid cutting the fabric, jeans needles feature an extremely sharp tip and a stronger shank to prevent needle bending or breaking when pushing through a thick cloth. When dealing with these needles and textiles, synthetic or mixed threads, 100 percent polyester, stronger topstitching threads, and cotton-wrapped polyester should be used.

Leather Needles

Due to a tip that looks and operates like a chisel while in use, leather needles are sometimes referred to as chisel point needles. These needles should be used with genuine leather, suede, and difficult-to-sew projects, but not with PU imitation leather, ultra suede, or synthetic suede since the properties of these materials vary significantly from their true equivalents.

Metafil Needles

A metafil needle is great for sewing or embroidering on woven or knitted materials. Metallic needles feature a larger eye, which allows these elegant threads to go through more readily and avoid shredding or splitting throughout the stitching process. A metallic needle would be an excellent investment if you have trouble threading your needle since it is also suitable for ordinary stitching and is much simpler to thread owing to the wider eye.

Top Stitch Needles

Topstitch needles feature an exceptionally sharp tip that readily pierces various kinds of cloth, and the big eye allows for the use of thick topstitching thread.

Wing Needles

Wing needles, when used in combination with your machine’s specific stitch choices, will create holes in the cloth to mimic drawn thread work. These needles should be used with fabrics composed of natural fibers, such as cotton.

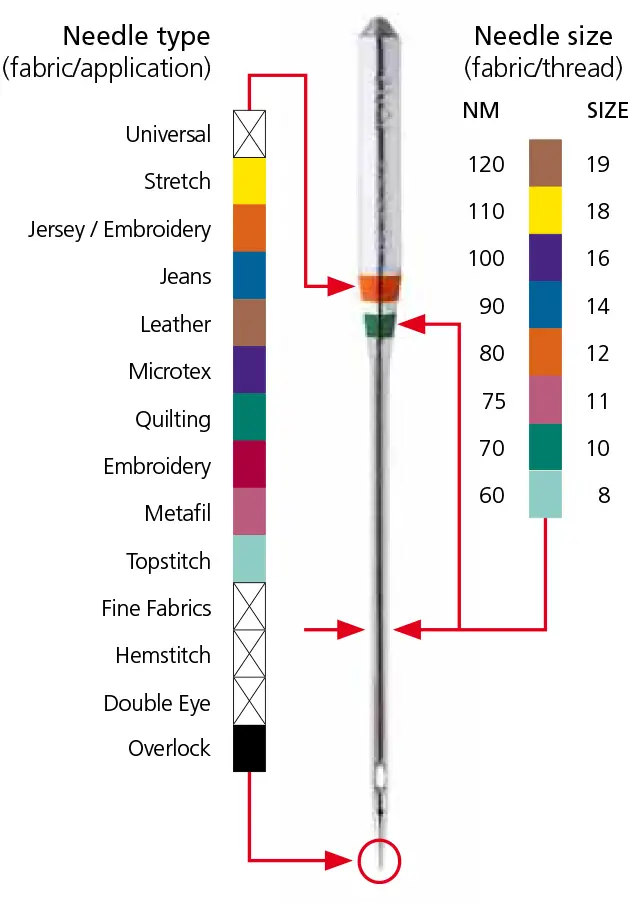

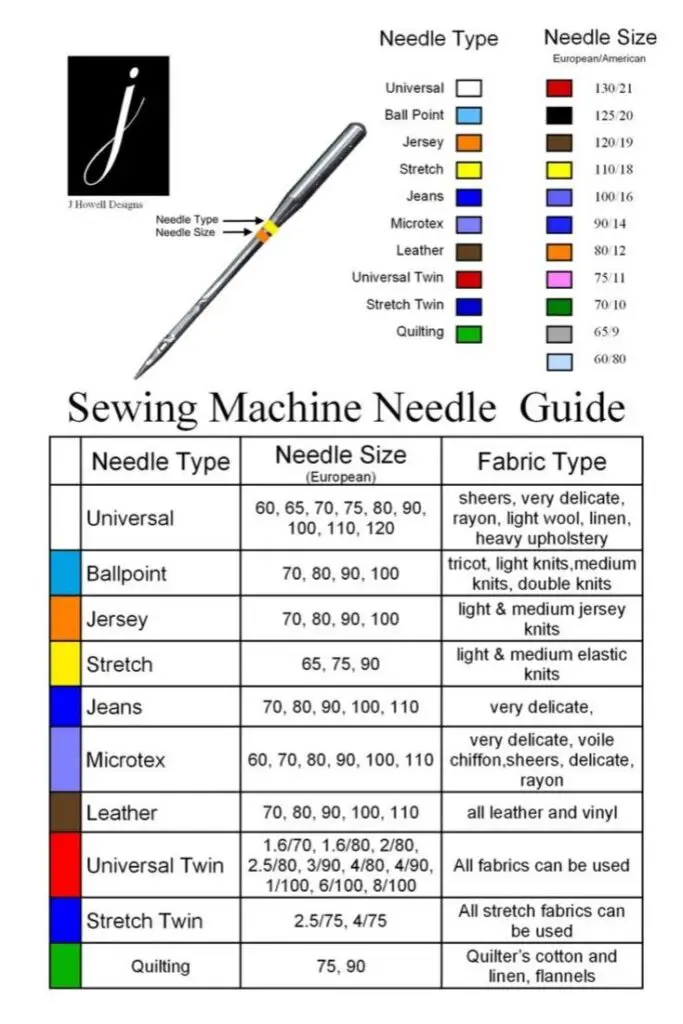

What do the sizes on sewing machine needles mean?

You may be wondering what the size numbers on sewing machine needles, such as 80/12 or 110/18, indicate. Now you don’t have to wonder any longer! One number represents the European size, while the other represents the American size. European sizes vary from 60 to 110 from thinnest to thickest, while American sizes range from 8 to 18. An 80/12 needle is often used for dressmaking (and is likely the needle size that came with your sewing machine).

When Should I Replace My Needle?

After each project, we suggest that you change your needle. Needles are quite inexpensive, so they won’t break the budget, and you’ll know that your needle will always operate as planned.

If your machine has stuck, we also suggest visually inspecting the needle. Jamming may cause the needle to flex, resulting in unanticipated outcomes such as poor stitch quality. If your machine makes a strange pounding sound when the needle enters the cloth, it’s time to replace the needle.

How Do I Replace a Needle?

The first step in replacing a needle is to place a piece of paper beneath the foot. There is no risk of the old needle falling into the machine while freeing the needle screw. We don’t want to be saddled with any hefty repair fees! Because of the shank design, the new needle will only fit in the right orientation after the old needle has been removed. The flat side of the shank should be towards the sewing machine’s back.

Before tightening the needle screw, make sure you push the new needle up as far as it will go. If you don’t, your stitch quality may suffer, your needle may impact the bobbin case, or your needle threader may be broken.